Sunscreen is having a huge moment with SPF products seeing notable sales increases year-round instead of just the typical warmer months. Consumers have fully embraced that anti-aging begins with sun protection thanks to education from experts, and growing awareness that all skin tones need protection from the sun. As a brand developing your own SPF product, there are multiple factors to consider when choosing the right approach (chemical, mineral/physical or hybrid) for your target audience.

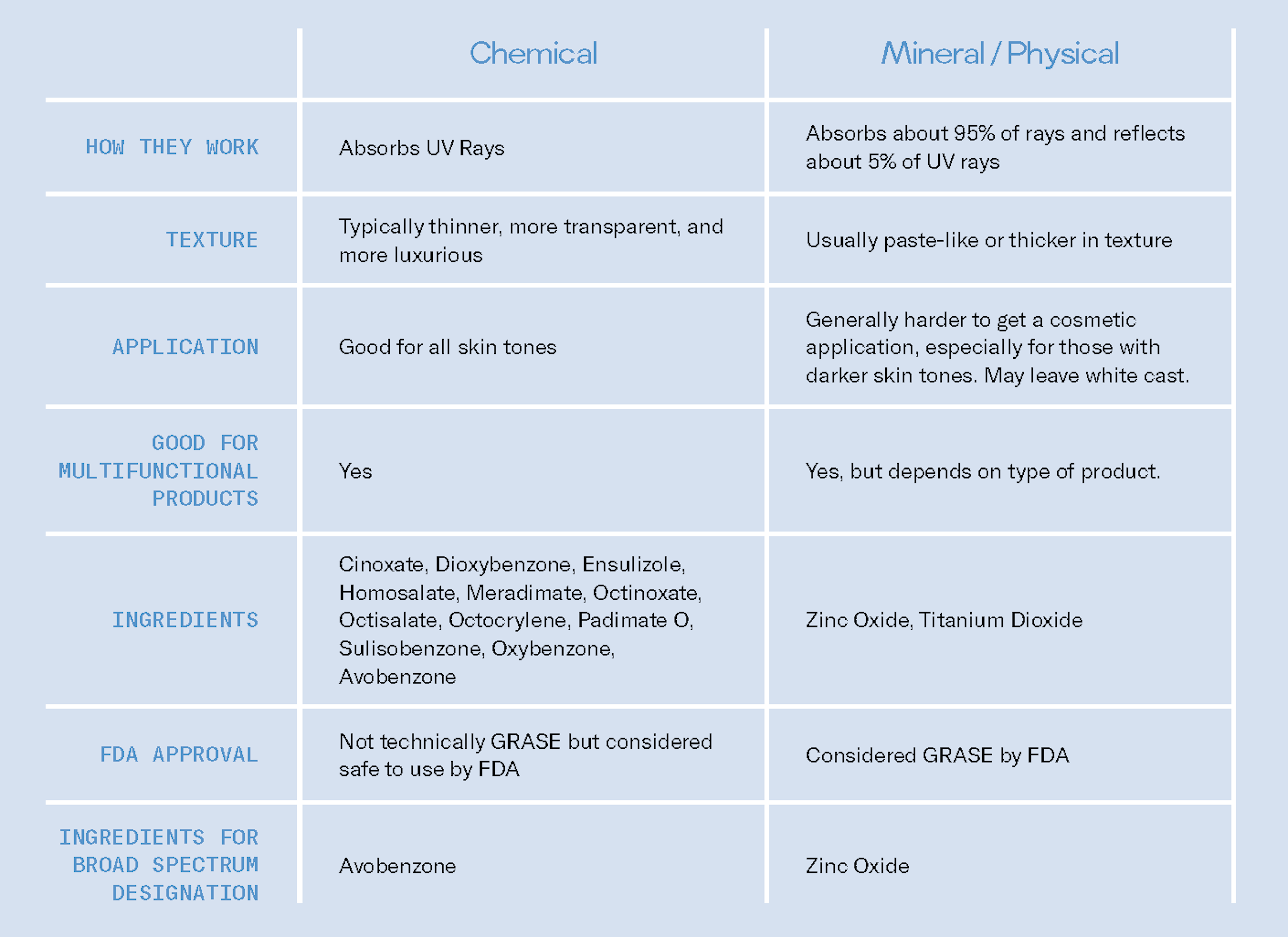

Ingredients and Regulations

Although both chemical and mineral sunscreens can be equally effective in preventing sun damage, there’s been growing requests for mineral sunscreens due to an increasing demand for natural products in the personal care industry. There is a perception by consumers that mineral ingredients are more natural despite the reality that these minerals must be chemically processed to remove impurities and other contaminants to get the pure form that is used in sunscreens.

The “cleaner” perception of mineral ingredients may also be tied to the FDA only designating the mineral ingredients (zinc oxide, titanium dioxide) as GRASE (generally regarded as safe and effective). The FDA does consider 12 chemical actives (see chart below) as safe to use but not technically GRASE, as they are still gathering data and reviewing research because additional data is needed to show that these sunscreens are GRASE.

Hybrid sunscreens are another approach and typically used to achieve the broad-spectrum designation. These are sunscreens that protect against both UVA and UVB rays, and are dependent on the actives used in the product. Most SPF actives will block UVB rays, but avobenzone (chemical) and zinc oxide (mineral) are the only two actives currently approved by the FDA that provide true broad-spectrum protection against the whole UVA spectrum.

Texture

A primary difference between chemical and mineral sunscreen is in the texture. Chemical sunscreens tend to be thinner and more transparent, while mineral sunscreens are thicker in texture and can leave a white cast because the mineral ingredients are not soluble. One way to work around this is to create a product with a tint, which can make it a multitasking beauty product, another category that is seeing growing popularity in the personal care industry. While minerals have come a long way in terms of textures you can achieve, chemical SPF is still regarded as superior in providing a more luxurious texture and application.

Unregulated Designations

“Reef Safe” or “Reef Friendly” is an unregulated designation that has been gaining in popularity as consumers become more interested in purchasing products that will not harm the environment. "Non-nano” mineral actives, meaning they are larger than 100 nanometers, are considered the most reliably “reef safe” ingredients. They are probably the most prudent option if you’re looking to add a “reef safe” claim to your product.

Studies vary on whether chemical sunscreens are harmful to reefs but there has been some legislation to ban specific ingredients. In 2021, Hawaii was the first state in the US to ban the sale of sunscreen containing oxybenzone and octinoxate because they’ve been found in some studies to contribute to coral bleaching.

Whether it’s the ingredients, regulations or texture, your Prime Matter Labs Account Manager can help you navigate through the many factors you must consider when developing or reformulating your SPF product.